Bestobell Steam Traps

Engineered for Efficiency, Built for Performance

At Bestobell Steam Traps, we are committed to delivering high-performance steam solutions that enhance system efficiency, reduce energy costs, and improve operational reliability. Our innovative steam trap designs ensure maximum condensate removal with zero live steam loss, providing long-term savings and sustainability for industrial applications.

Our Steam Trap Solutions

Delta Element Steam Traps

Our patented Delta Element Steam Traps offer a unique single-blade element design that combines thermostatic and thermodynamic principles for superior performance. These traps provide steam-tight shutoff, eliminating energy waste and maximizing efficiency. Stainless steel internals ensure durability and resistance to corrosion, while modulating discharge automatically adapts to pressure and load variations. Backed by a three-year warranty, the Delta Element traps guarantee no live steam loss.

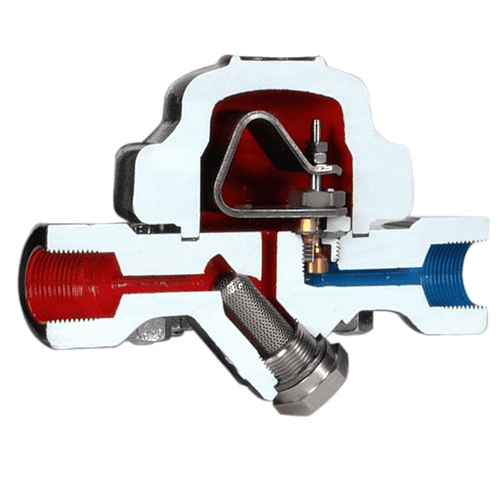

Disc Traps (DT711 Series)

The DT711 Series is designed for high-pressure applications up to 711 psi, offering a compact, thermodynamic design with a single moving part. Engineered to withstand extreme conditions, these traps are resistant to freezing and water hammer. Their fail-open safety feature ensures continued system protection, making them ideal for superheated steam applications. Available in NPT or BSP end connections.

High-Pressure Steam Traps (DM40/64/100/160/320 Series)

For the most demanding industrial environments, our DM Series steam traps deliver unmatched reliability with operating pressures ranging from 250 psi to 2000 psi. The robust stainless steel construction, combined with a modulating discharge, optimizes condensate removal while preventing live steam loss. Continuous venting of air and CO₂ enhances heat transfer and minimizes corrosion risks, ensuring maximum system efficiency.

Total Traps

Designed for saturated steam applications, our Total Trap stations provide a compact, all-in-one solution for condensate discharge in high-temperature environments. With working pressures up to 2000 psi and temperatures up to 1000°F, these units ensure reliable performance in critical steam applications.

Why Choose Bestobell?

- Proven Performance – Decades of engineering expertise in steam system optimization.

- Energy Efficiency – Advanced designs eliminate live steam loss for maximum savings.

- Reliability & Durability – Stainless steel internals for long-lasting performance.

- Comprehensive Support – Technical experts available to assist with product selection and system optimization.

Have a specific question about Bestobell Steam Trap products?

We're Here to Help!

Delta Element/Bi-Metallic Steam Traps

Delta Element/Bi-Metallic Steam Traps  Float & Thermostatic Traps

Float & Thermostatic Traps  Inverted Bucket Traps

Inverted Bucket Traps