FD Series

Excellent Stability Over A Wide Flow Range; Smooth Computer Automation; Precision Pressure or Automated Flow Control

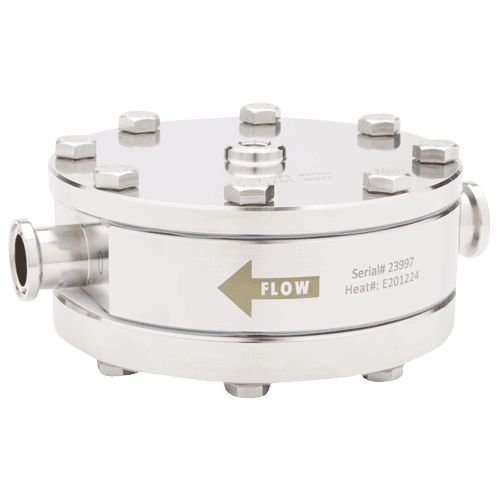

Equilibar® FD Series Sanitary valves feature Equilibar's novel dome-loaded multiple orifice technology delivering instantaneous control, frictionless operation, and superior precision across an exceptionally wide flow rate range. They are used in pressure or flow control applications. To learn more about the FD Series Active Damping System, download the brochure.

The FD Series valves offer unmatched advantages in sanitary applications such as gradient chromatography, inline conditioning, tangential flow filtration (TFF), transmembrane pressure control (TMP), tank blanketing, and liquid dosing.

For pressure control, simply apply an inert gas pressure to the dome of the valve equal to the desired setpoint and the regulator does the rest. The dome pressure forces a flexible diaphragm down onto a plate of parallel orifices. A rise in inlet pressure lifts the diaphragm up to allow excess pressure to be relieved through the outlet orifices. Conversely, a loss of pressure at the valve inlet causes the diaphragm to be pushed closer to the orifices, restricting flow and rebuilding pressure upstream.

For flow control, connect an electronic pilot regulator and flow meter in a PID loop with the FD valve and it will adjust to control flow. This type of flow control is an excellent choice for buffer dilution requiring varying flow rates to create different buffer pH recipes.

Unsurpassed pressure control performance – Traditional back pressure regulators use springs to gradually open up as the overpressure is used to compress the spring. This often results in significant inlet pressure loss with increases in process flow. The FD Series features ultra-sensitive diaphragm-operated back pressure technology capable of controlling pressure with high precision over a wide range of flows. They fully open in less than 1% overpressure in most applications.

Simple compact design – The FD sanitary regulators are easy to disassemble for maintenance, reassemble, and return to use quickly and easily. The compact design facilitates a simple process layout.

CIP/SIP Compatibility – The FD Series are made of SS316L stainless steel and USP Class VI diaphragms. The design is compatible with temperatures up to 275°F (135°C) experienced during steam sterilization, and the valve’s wide working flow range allows one FD size to effectively control during high flow CIP rates as well as very low flow dosing rates.

Smooth computer automation – The FD Series responds instantaneously to changes in process flow or setpoint to main the desired inlet pressure. Because of its capacity to control within milliseconds, the FD Series is a perfect match for computer automated control. Paired with an electronic pilot regulator, the FD regulator may be connected to the process control system, and it is ready for automation.

Pressure control or flow control: The FD valve is versatile and can be used for pressure control or as an automated flow control valve.

FD02

Port Size: 1/4″

Max Pressure: 150 psig/10 bar(g)

Cv Range: 1E-6 to 0.2

Body Material: SS316L; Hastelloy C; Custom

FD03

Port Size: 3/8″

Max Pressure: 150 psig/10 bar(g)

Cv Range: 1E-6 to 0.6

Body Material: SS316L; Hastelloy C; Custom

FD04

Port Size: 1/2″

Max Pressure: 150 psig/10 bar(g)

Cv Range: 1E-6 to 1.0

Body Material: SS316L; Hastelloy C; Custom

FD06

Port Size: 3/4″

Max Pressure: 150 psig/10 bar(g)

Cv Range: 1E-5 to 4.0

Body Material: SS316L; Hastelloy C; Custom

FD08

Port Size: 1″

Max Pressure: 150 psig/10 bar(g)

Cv Range: 1E-5 to 8.0

Body Material: SS316L; Hastelloy C; Custom

FD012

Port Size: 1-1/2″

Max Pressure: 150 psig/10 bar(g)

Cv Range: 1E-4 to 12

Body Material: SS316L; Hastelloy C; Custom

FD016

Port Size: 2″

Max Pressure: 150 psig/10 bar(g)

Cv Range: 1E-4 to 19

Body Material: SS316L; Hastelloy C; Custom

FD024

Port Size: 3″

Max Pressure: 150 psig/10 bar(g)

Cv Range: 1E-3 to 36

Body Material: SS316L; Hastelloy C; Custom

Pulsation Dampening Solutions for Sanitary Flow Stability

Enhancing Stability in Biopharmaceutical and Food Processing

Sanitary Tank Blanketing for Precise Low-Pressure Gas Control

Optimizing Inerting in Food and Biopharmaceutical Processing

Minimizing Flow Pulsations in Chromatography Skids

Advancing Pulsation Control with Active Dampening Technology

Optimizing Tank Blanketing in API Pharmaceutical Processing

Key Design Considerations for Inert Gas Blanketing

Optimizing Pressure Control in Disc Stack Centrifuges

Back Pressure Control Using Steriflow Equilibar Sanitary Valves

Optimizing CIP Systems in Biopharmaceutical Manufacturing

FDO Series Sanitary Regulators Improve CIP Cycle

USP Class VI

CRN on some models contact Equilibar for details

Your List

Email List

Get A Quote

Quick Quote

Know what you need and want a quote quickly? We can help! Fill out this form and we will get back to you shortly.