Optimizing Pressure Control in Disc Stack Centrifuges

Back Pressure Control Using Steriflow Equilibar Sanitary Valves

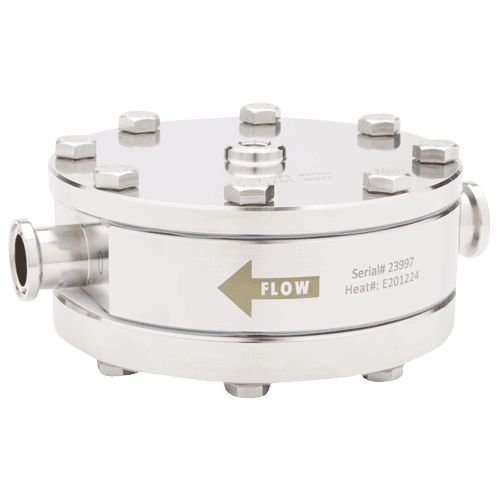

Centrate Back Pressure Regulation with Steriflow Equilibar® FDO valves

Disc stack centrifuges play a critical role in bioprocessing therapeutic monoclonal antibodies (mAbs) by providing efficient clarification without causing shear damage to cells. Using centrifugal force, these systems separate cellular debris from the liquid broth, producing a clarified supernatant that moves forward for further purification while ejecting solid waste.

During operation, culture fluid continuously enters the centrifuge, while the centrate (supernatant liquid) exits for further processing. Depending on the centrifuge design, solids are either discharged continuously or in batch intervals. Two key process parameters influence efficiency: flow rate (residence time) and back pressure on the centrate line. The centrate back pressure valve plays a crucial role by helping maintain the correct bowl level, ensuring a hydro-hermetic process that prevents oxidation.

Choosing the Right Valve for Centrifuge Centrate Control

Back pressure regulators (BPRs) in disc stack centrifuge applications must perform consistently under both standard operating conditions and rigorous cleaning cycles. During normal operation, these valves must provide stable and precise pressure control at mild temperatures and low flow rates to ensure high-quality supernatant production. However, during cleaning cycles, they must withstand higher temperatures, increased flow rates, and exposure to caustic or acidic cleaning agents, with steam cleaning temperatures reaching 130°C.

The Steriflow/Equilibar FDO Advantage

The FDO sanitary back pressure regulator is specifically designed for this demanding environment. Its advanced dome-loaded, multiple-orifice technology offers:

- Instantaneous, frictionless operation for precise pressure control

- Exceptional durability against harsh cleaning agents and high temperatures

- A wide control range to accommodate varying flow conditions

Additionally, the vibrations inherent in centrifuge systems can accelerate wear and tear in traditional sanitary valves, which rely on complex stem assemblies with multiple moving parts. This often leads to increased maintenance and system downtime.

By contrast, the FDO features a single moving part—a supple diaphragm—which is held in place by dome pressure. As upstream pressure exceeds the setpoint, the diaphragm lifts slightly to release pressure, ensuring rapid, precise adjustments to process variations. This unique design minimizes wear, reduces maintenance, and enhances long-term reliability in bioprocessing applications.

Conclusion

For disc stack centrifuge centrate control, the FDO provides a robust, precise, and low-maintenance solution. Its superior pressure control and durability in extreme conditions make it an ideal choice for ensuring efficient, oxidation-free clarification in biopharmaceutical manufacturing.

Quick Quote

Know what you need and want a quote quickly? We can help! Fill out this form and we will get back to you shortly.

FDO Series

FDO Series