Sanitary Tank Blanketing for Precise Low-Pressure Gas Control

Optimizing Inerting in Food and Biopharmaceutical Processing

In food and biopharmaceutical processing, maintaining a controlled tank environment is critical to preserving product quality. Sanitary tank blanketing is a widely used method where an inert gas layer (such as nitrogen) is maintained above the process media to prevent oxidation, moisture contamination, or unwanted reactions.

Also known as inerting, this process requires precise low-pressure control, as the blanketing gas must be kept slightly above atmospheric pressure to ensure optimal protection. A tank blanketing system typically includes:

- A pressure-reducing valve (PRV) to supply inert gas into the tank.

- A back pressure regulator (BPR) or “de-padding” valve to release excess gas and maintain pressure at the exact setpoint.

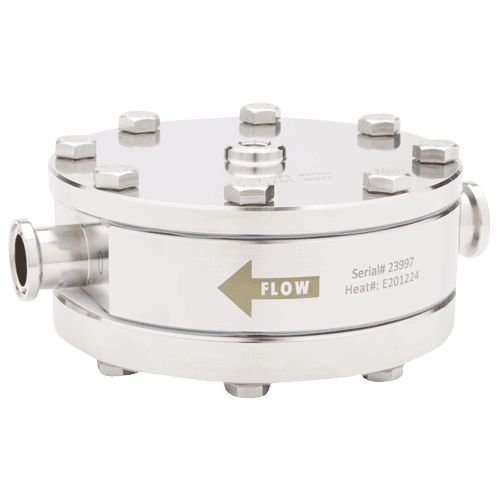

For food and biopharmaceutical applications, the de-padding valve must meet sanitary standards and be constructed from FDA-approved or USP Class VI materials. Steriflow/Equilibar’s FDO sanitary back pressure regulator (BPR) is an ideal choice due to its instantaneous response, ultra-low pressure control, and sanitary design.

How the Steriflow/Equilibar FDO Regulator Optimizes Tank Blanketing

In the schematic below, an Steriflfow/Equilibar FDO sanitary BPR controls tank headspace pressure in a bioprocessing application where nitrogen is used as the inert gas.

- Sparging gas is introduced at the bottom of the tank to aid in cell growth.

- Nitrogen gas is added at the top to create the protective blanket.

- Process fluctuations due to temperature, level changes, or gas sparging can cause pressure variations inside the tank.

Because bioprocessing environments require precise and stable conditions, the Steriflow/Equilibar FDO BPR is designed to respond instantaneously to pressure changes, maintaining the low setpoint pressure required for optimal processing.

Why Choose the Steriflow/Equilibar FDO for Sanitary Tank Blanketing?

- Unmatched Precision – Maintains ultra-low pressure control (down to inWC/mbar ranges) without over-pressure issues.

- Instantaneous Response – The patented dome-loaded multiple orifice design ensures fast, accurate adjustments.

- Wide Flow Range – Works across a broad range of flow rates, making it more versatile than traditional spring-loaded valves.

- Sanitary Compliance – Available in USP Class VI and FDA-approved materials, meeting stringent food and biopharma requirements.

- No Hysteresis or Cracking Pressure – Adjusts smoothly to minute pressure fluctuations, ensuring process stability.

- Easy Maintenance – Simple design with fewer moving parts reduces maintenance downtime.

Conclusion

For food and biopharmaceutical tank blanketing applications, the Steriflow/Equilibar FDO sanitary BPR offers a superior solution by delivering fast, precise, and reliable low-pressure control. Its innovative diaphragm technology and sanitary design make it a preferred choice for ensuring optimal product protection and process consistency.

How Can We Help You With Your Sanitary Processes?

Learn more about how our Back Pressure Regulators can protect your sanitary process.

FDO Series

FDO Series