Understanding the Differences Between Sanitary Back Pressure Regulators and Sanitary Safety Relief Valves

Learn how back pressure regulators and safety relief valves can protect your sanitary process.

When designing or maintaining sanitary systems, understanding the distinct roles and functions of sanitary back pressure regulators (BPRs) and sanitary safety relief valves (SSRVs) is crucial. Both components are essential for managing pressure in fluid systems, but they serve different purposes and operate in fundamentally different ways. This guide will navigate these differences and choose the right equipment for your application.

Purpose and Function

Sanitary Back Pressure Regulators

A sanitary back pressure regulator is designed to maintain a set upstream pressure by continuously controlling the flow or fluid. If upstream pressure builds up above the set point, the BPR will open just enough fluid to release fluid and bring the pressure back to the desired setting. It ensures that the pressure in the system stays within a specified range, making it ideal for processes requiring consistent pressure to ensure product quality or system performance.

Key Features of Back Pressure Regulators:

- Regulate upstream pressure to a desired setpoint

- Provide smooth and continuous control of pressure

- Essential for processes requiring precise pressure stability

Sanitary Safety Relief Valves

In contrast, a sanitary safety relief valve is a safety device that protects the system from overpressure conditions. It is designed to open quickly when the system pressure exceeds a predetermined limit, venting excess pressure to prevent equipment damage or catastrophic failure. It does not provide process control during standard operating conditions but comes into action only during out-of-control situations.

Key Features of Sanitary Safety Relief Valves

- Provides safety by releasing pressure rapidly in overpressure conditions

- Operates as an emergency device rather than a control mechanism

- Designed to comply with safety standards and prevent system hazards

Difference in Operation

Smooth Control vs Emergency Response

BPRs: Provide smooth, continuous pressure regulation, ensuring that upstream pressure remains steady in order to optimize the process and product quality. They are designed for control rather than safety, meaning they cannot relieve pressure as quickly as an SSRV in a high-pressure, emergency scenario.

SSRVs: Are not designed for continuous process control and are not suitable for maintaining a steady pressure. Instead, they operate by quickly releasing pressure at a predetermined pressure rating by sending process fluid out of the primary process stream. This rapid response is essential for safety but makes them unsuitable for precise pressure regulation. They are a fail-safe in the system and are intended to only operate as a last resort.

Application Scenarios

BPRs: Best suited for applications requiring stable upstream pressure, such as maintaining flow rates or preventing cavitation in pumps. Steriflow Valve and Equilibar have a complete line of back pressure regulators for bioprocessing applications from clean utility to tank blanketing and from bioreactor to filtration control.

SSRVs: Critical for protecting systems from sudden overpressure that could lead to equipment damage or safety hazards. Steriflow Valve has a selection of sanitary safety relief valves with a wide range of pressure ratings to protect your bioprocess systems. They are ASME Section VIII compliant and CE/PED certified.

Steriflow Valve is here to help you with the pressure control your bioprocessing system needs. If you have further questions about selecting the right equipment for your system, our team is here to help.

How Can We Help You With Your Sanitary Processes?

Learn more about how our Back Pressure Regulators and Safety Relief Valves can protect your sanitary process.

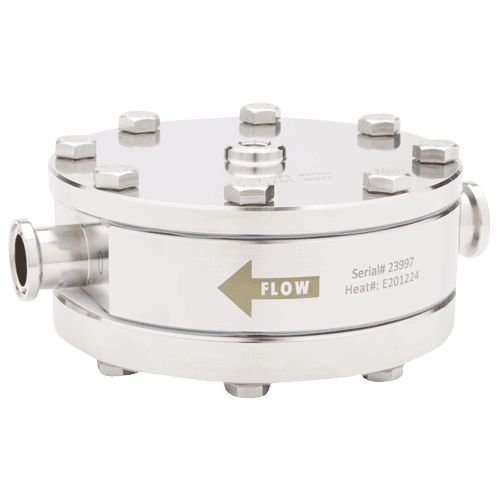

Sanitary Safety Relief Valves

Sanitary Safety Relief Valves  Mark 95 Sanitary Back Pressure Regulator

Mark 95 Sanitary Back Pressure Regulator  Equilibar FDO Sanitary Back Pressure Regulator

Equilibar FDO Sanitary Back Pressure Regulator